Thermal grade

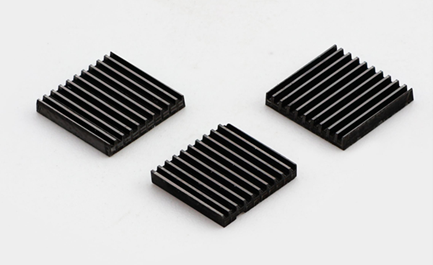

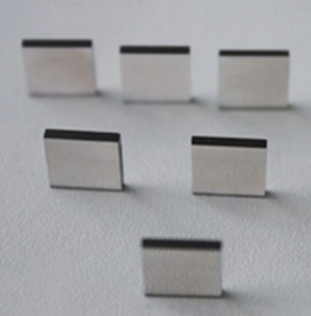

With low coefficient of thermal expansion and the highest thermal conductivity, CVD can be used in the third generation semiconductor high power devices, high power lasers and microelectronic thermal sink devices,

Synchrotrons and X ray free electron laser beamlines heat disspiation with special bondingcentralized heat dissipation of large areas, such as TR components, microwave power components point heat dissipation for thermal emission units, such as Gallium nitride(GaN) devices

We can also provide customer solution for different material bonding.

| Size | Single crystalline < Φ 30mm Polycrystalline < Φ 90mm |

| Roughness growing side | ˂30nm polish |

| Thermal conductivity | 1200-2300W/mK |

| Thermal expension | 293K 0.8×10-6

/K 400-1200K (1.5-4.8) x10-6 /K |

| Isobaric molar heat capacity | 1800K 24.7J/mol.K 3000K 26.3J/mol.K |

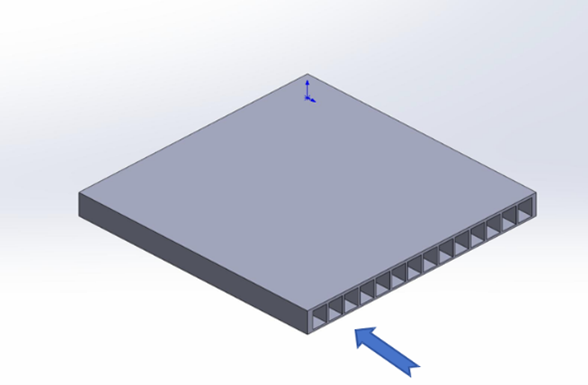

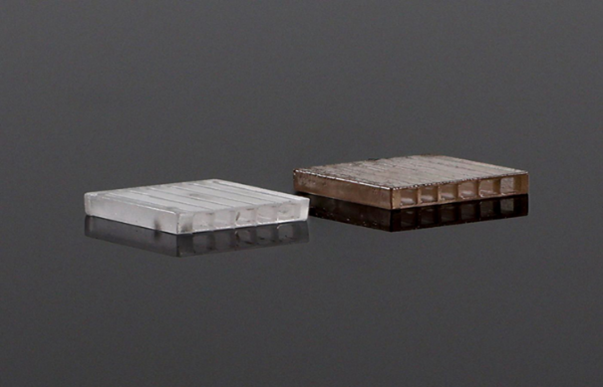

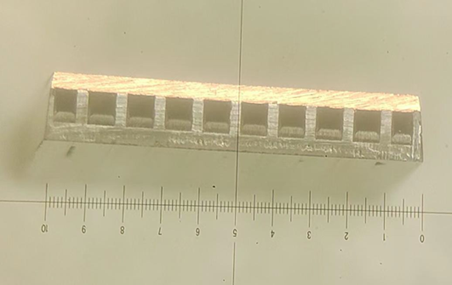

CVD diamond micro channel

New method of heat management. Heatcan be taken away by water flow through the CVD diamond microchannel. There are two options.

Option 1: CVD channel direct by laser etching

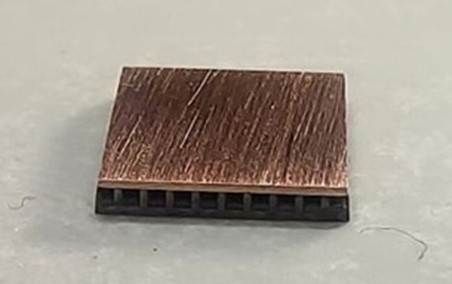

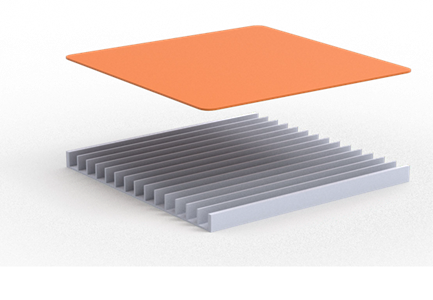

Option 2: Laser etchingand adhesive the cover

Cover can be different kind of materials, CVD diamond, copper or any metals. Adhesive with glue. This must pay attention to the water temperature, fluiding speed and water pressure to ensure the bonding firmness.