Boron Carbide B4C

Boron Carbide is an extremely hard boron – carbon ceramic, only inferior to cubie boron nitride

(cBN) and diamond, people also call it black diamond This imparts exceptional wear- and

abrasion – resistant properties, enabling B4C used in the demanding application areas, like

- Control rod, shut down pellets shelds in nuclear industry.

- Neutrons absorbs in Laser and synchrotron-

- Abrasives for lapping and ultrasonic cutting

- Anti-oxidant in carbon-bonded refractory mixes

- Wear-resistant blasting nozzles, wear drawing dies, ceramics forming dies

| Density [g/cm2] | 2.51 |

| Flexual strength [Mpa] | 560 |

| Modulus of elasticity [Gpa] | 450 |

| Four points rapture strength [Mpa] | 237 |

| Knoop hardness [GPa] | 39.2 |

| Compressive strength [MPa] | 1052 |

| Fracture toughness [MPa.m½] | 3.37 |

| Heat conductivity [W/m.k] | 36.128 |

| Thermal expansion@500°C | 4.77×10-6 |

| Thermal expansion@700°C | 5.18×10-6 |

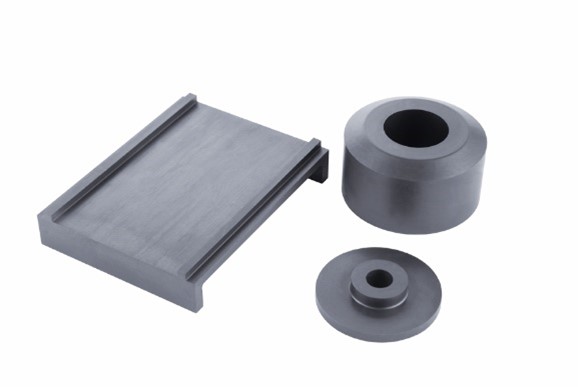

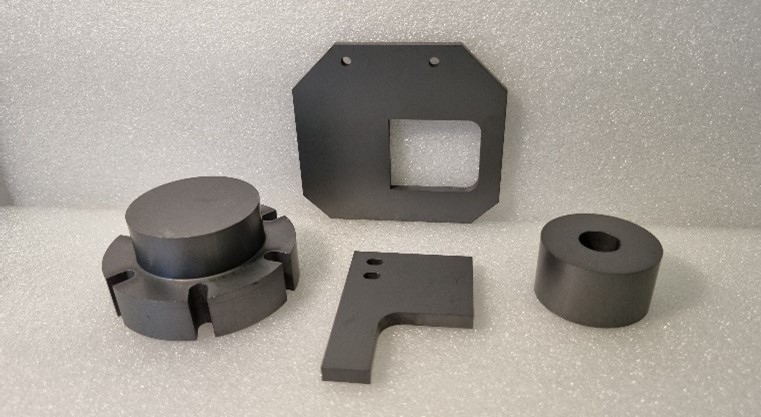

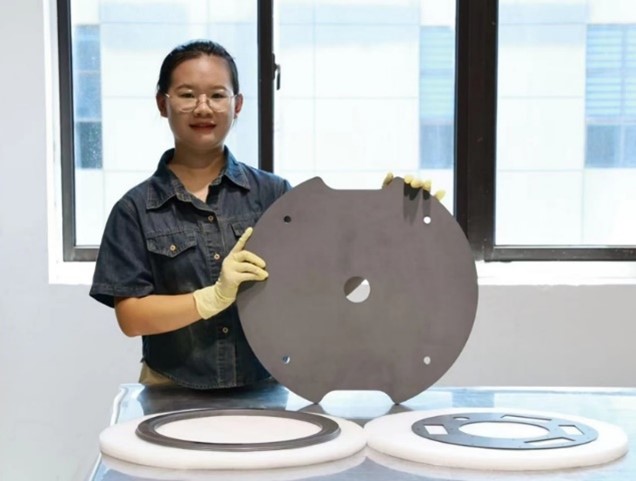

We can supply B4C ceramics in different shape and dimension. Following is our material

chemical composition and sintering products standard specification

| Total Boron | 77.14 |

| B2O3 | 0.10 |

| Free Boron | 0.44 |

| Boron Compound | 76.70 |

| Total Carbon | 20.03 |

| Free Carbon | 2.65 |

| Carbon Compound | 17.38 |

| Fe2O3 | 0.28 |

| B4C total | 94.08 |

| Maxi. Dimension | 450x450x50mm |

| Purity of B4C | 99.5% |

| Density | ≥2.5 |

| Standard tolerance** | ±0.1, ±0.5mm (irregular shape) |

| Normal Roughness | |

| Mini. Drill hole Diameter | 3mm |

| Parallelism and verticality | ±0.1mm |

*All the exact data are subject to our final production drawing

** tolerance depends on the production difficulties and shape

** tolerance depends on the production difficulties and shape