mechanical grade

ultra-hardness, wear resistance and corrosion resistance, diamond is the core consumable of the processing tools for sawing, cutting, grinding and drilling. Diamond is widely used in the tools for various precision machining and the surface of the drill in geological exploration fields. Large size, high quality single crystal CVD diamond can be used in brain/heart surgery scalpel, optical lens cutting and other high-end expansion fields, CMP process of semiconductor industry.

| hardness | 10400kg/mm2 |

| Yang’s modulus | 1100-1300GPa |

| Roughness (both sides) | ˂30nm, polished |

| Face orientation | 100 |

| Edge orientation | 110 |

CMP Pad conditioner

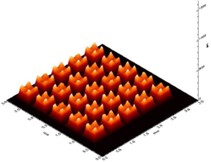

This product is the first conditioning disk with one-piece syntenic single crystal diamond (SSCD) array in the world. It can tremendously optimize the Removal rate, within wafer non-uniformity, micro scratch control, avoid overcutting the pad, extend the disk and pad life, thus can reduce the CoC and equipment down time, increase the CMP efficiency and wafer yield.

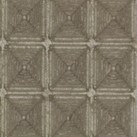

1. The array is made by 6x8mm single crystal diamond with laser sculpturing. This solves the problem of multi crystalline diamond grit chipping scratch the wafer.

2. All the tips on the array are leveled with same height and angle, penetrate the pad shallow and even, thus can increase both pads wearing life and conditioning disks life.

3. Diamond tips height, angle, pitch can be customized by CAD, to fit the individual CMP processes.

4. Removal rate, within wafer non-uniformity micro scratch control can all be optimized.